Electrical & Mechanical Characteristics

Conductor: Tinned copper / Silver-plated copper

Resistance: ≤ 1 kΩ (typical)

Capacitance: Low-capacitance design for ECG signal accuracy

Noise Performance: Optimized for motion artifact reduction

Wire Gauge: AWG 30–32

Conductor Structure: Fine-stranded, ultra-flexible

Jacket Material: Medical-grade TPU / Silicone

Outer Diameter: 2.0–2.5 mm (typical)

Bending Life: ≥ 100,000 cycles

Strain Relief: Reinforced at electrode and connector ends

Technical and specification details

1.Designed for Reliable and Long-Term ECG Monitoring

Whether used in hospital ECG monitoring, portable ECG monitoring, or home ECG monitoring, our ECG leadwires focus on:

•Consistent signal quality

•Mechanical durability under repeated bending

•Stable performance during long-term and continuous ECG monitoring

Each leadwire set is designed to support reliable ECG monitoring while maintaining ease of use for both clinicians and patients.

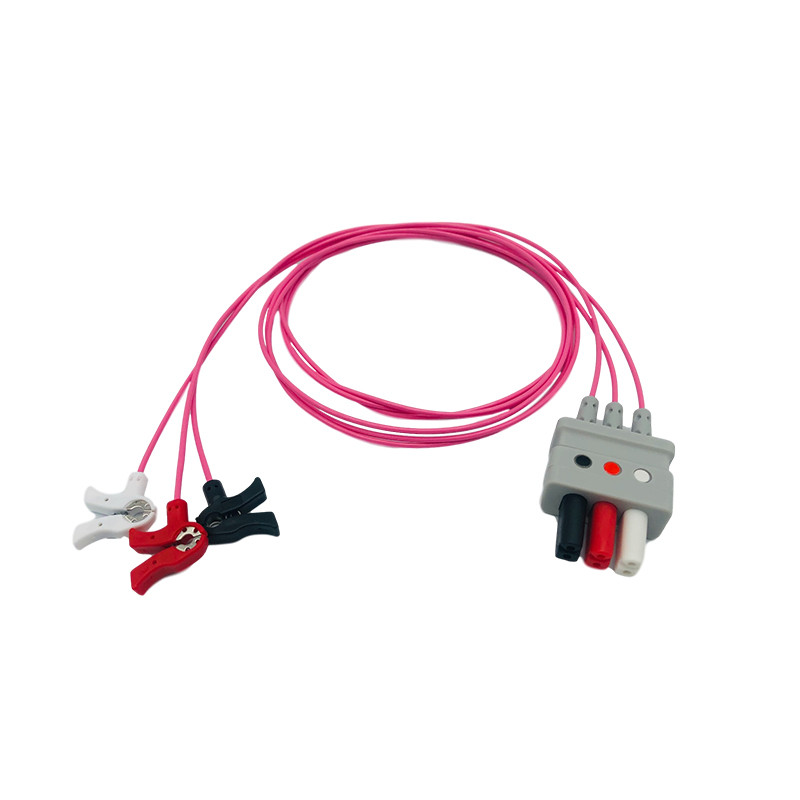

2.Configurations for Different ECG Monitoring Systems

To match various ECG systems and clinical requirements, ECG leadwires are available in multiple configurations, including:

•3-lead and 5-lead ECG leadwire sets for basic and bedside ECG monitoring

•10-lead ECG leadwires for standard 12-lead ECG monitoring

•Custom leadwire sets for ECG Holter monitors, portable ECG monitors, and wearable ECG devices

Leadwire length, branch layout, and connector orientation can be customized to suit hospital ECG monitors, home ECG monitors, and portable ECG monitoring devices, ensuring ease of use and reliable patient connection.

Compliance and Certification

1.Connector Compatibility with ECG Equipment

On the equipment side, ECG leadwires are compatible with a wide range of ECG monitors and ECG equipment, including:

•Standard ECG trunk cable interfaces

•Brand-specific ECG monitor connectors (such as GE-compatible ECG leadwires)

•Custom interfaces for portable ECG monitors and ECG monitoring devices

This allows seamless integration with ECG equipment for sale, hospital ECG monitors, and ECG monitoring systems, without compromising signal quality or mechanical reliability.

2.Application

•Patient monitoring

•Diagnostic ECG systems

•Holter & wearable ECG devices

Core Competencies and Differentiation

1.Low-Noise Design for Accurate ECG Signal Acquisition

As ECG leadwires are directly connected to the patient, low-noise performance is critical for accurate ECG waveform capture.

To reduce motion artifacts and electrical interference, ECG leadwires may incorporate:

•Fine-stranded conductors with optimized flexibility

•Conductive or semi-conductive coatings on individual cores to reduce triboelectric noise

•Dedicated shielding or twisted-pair structures for improved noise rejection

•Balanced impedance control to maintain signal stability during movement

These design elements are especially important for continuous ECG monitoring, Holter ECG monitoring, and wearable ECG monitoring devices, where patient motion is unavoidable.

2.Jacket Materials Optimized for Patient Comfort

Patient-side ECG leadwires require materials that balance softness, durability, and biocompatibility.

Common jacket materials include:

•TPU / TPE for flexibility, abrasion resistance, and easy cleaning

•PVC for cost-effective disposable ECG leadwires

•Silicone for ultra-soft touch, long-term skin contact, and wearable ECG applications

Material selection can be optimized based on home ECG monitors, hospital ECG monitoring devices, or wearable ECG monitors, ensuring both patient comfort and product longevity.

3.Pediatric and Neonatal Electrode Interfaces (Optional Customization)

For pediatric or neonatal ECG monitoring, leadwires can be designed with miniaturized patient connectors to reduce pulling force and improve patient comfort.

•Smaller contact area

•Enhanced flexibility

•Reduced stress on electrode pads

Shenzhen Qiaoli Technology Co., Ltd. understands that perfect equipment connectivity requires a touch of personalization. Our standard specifications are merely the starting point.

✅ Flexible customization: We can collaborate to meet specific requirements, including precise length, customized color coding, special shielding needs, or compatibility with specific connectors.

✅ Compliance Assurance: All customized solutions are developed under our ISO 13485 system, ensuring full compliance with the stringent standards of the medical industry.

✅ Start with samples: We recommend testing with prototype samples to ensure full compliance with your device integration requirements.

Let us provide you with the most suitable solution.